Pre-Engineered buildings are a predetermined inventory of raw materials that has proven over time to satisfy a wide range of structural and aesthetic requirements.

The components are engineered beforehand and standardized. Use of these standard components reduces the engineering, production and erection time. Use of customized software for design & drafting increases the speed of the projects.

The production line is highly sophisticated having Auto welders, multi-cutting torches, shear cutting machines etc., which greatly reduce the time of fabrication of built-up components.

Roll forming machines for producing Z & C members and sheeting. having standard dimension, increases the production capacity of secondary members. use of standard accessories greatly increases the speed of production & erection.

Buildings are typically delivered in just a few weeks after approval of drawings. Foundation and Anchor Bolts are cast in parallel with manufacture of the building. Site assembly is fast, as all building components are delivered finished, ready for site bolting. Our study shows that in India the use of PEB will reduce total construction time on a project by at least 50% .This will allow faster occupancy and earlier realization of revenue.

Due to the systems approach, there is a significant savings in design, manufacturing and site erection cost. The structural elements are shaped to follow the stress diagram of the member, thus reducing weight, cost and load to foundation. The secondary member and cladding nest together reduces transportation cost.

Building can be easily expanded in length by adding additional bays. Also, expansion in width and height is possible by pre-designing for future expansion.

Building can be supplied to around 100-120 M clear span easily. A combination of built-up section and tubular truss helps in achieving highest economy for large span.

As buildings are manufactured completely in the factory under controlled condition, the highest product quality is assured.

Building are supplied with high quality paint system for cladding and steel to suit ambient condition at site, which results in long durability and low maintenance costs.

Building can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required ‘U’ values.

Buildings can be supplied with various types of fascia, canopies, and curved eaves and designed to receive pre-cast concrete wall panels, curtain walls, block walls and other wall systems.

As the complete building package is supplied by a single vendor compatibility of all the building components and accessories is assured. This is one of the major benefits of the pre-engineered building systems.

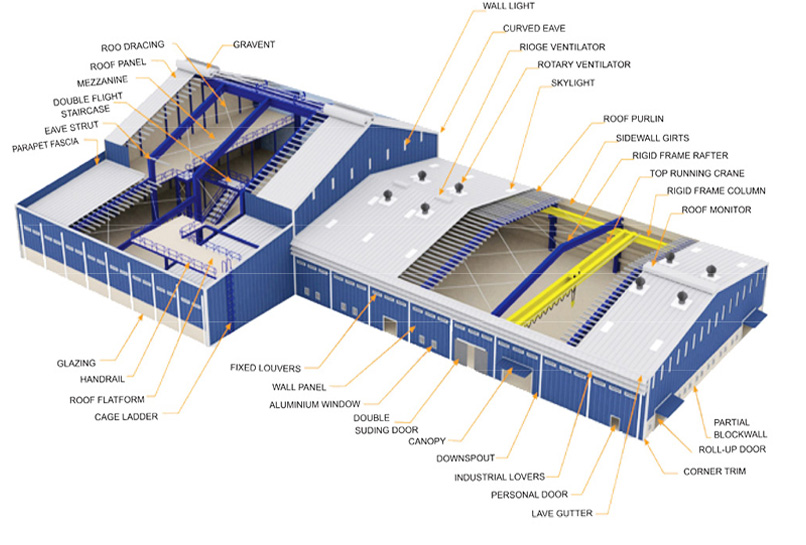

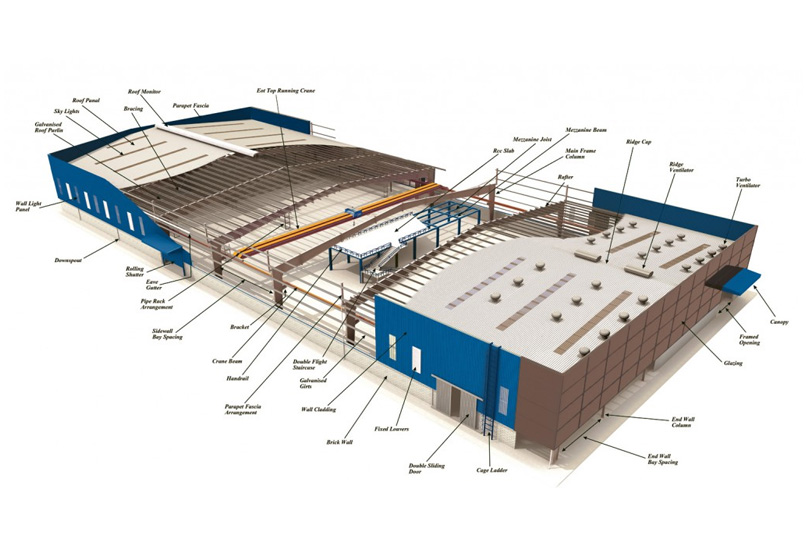

A typical assembly of a simple metal building system is shown below to illustrate the synergy between the various building components as described below:

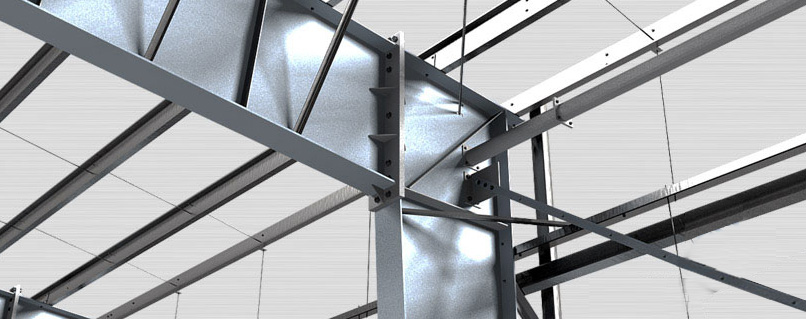

Moment resisting frames provide lateral stability and transfer the roof and wall loads to the foundation through anchor bolts.

Purlins and girts provide lateral bracing to the building columns and rafters preventing lateral buckling of the compression flanges.

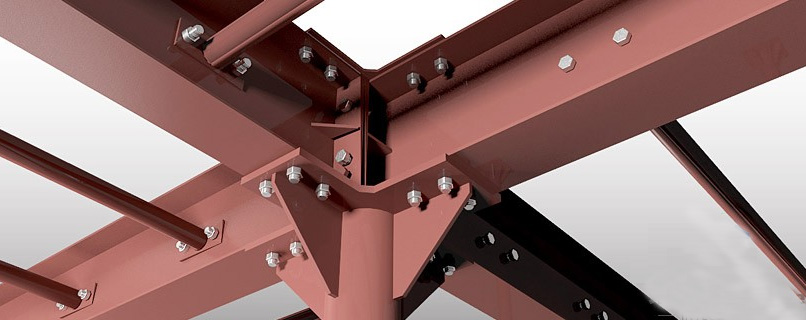

Anchor bolts are the interface between steel framing to the civil foundation to transfer the forces and moments to the ground. These bolts are designed to meet the structural loading for critical condition based on designer’s choice of connection vide pinned or fixed base connection as the framing has been designed for.Assembly hardware is critical components to design and made of high strength steel. Being factory made building concept, every member has to be designed in transportable length of about 10-12 mtr. In order to assemble all the members at site it is necessary to to have proper bolted connection system which is widely designed to take up erection forces as well as post environmental as well application forces.

Provides weather tight envelops and transfers structural loads like wind and live loads to the supporting secondary framing provides lateral bracing to the roof purlins and wall girts.

Being pitched roof, it is necessary to have properly designed drainage system vide Gutter & down pipes to transfer rain water from roof to the collection pot e.g. gutter and then discharge to the ground using down take pipes.

Due to the systems approach, the use of high strength steel, use of tapered built-up sections which are optimized by the computerized design program and the use of continues light gauge secondary steel section, there is an overall reduction in steel construction.

Although PEB systems are extensively used in industrial and many other non-residential constructions worldwide, it is relatively a new concept in India. These concepts were introduced to the Indian market latterly in the 1997’s with the opening up of the economy and a number of multi-nationals settings up their projects. Global PEB players have established their presence in India.

Following are some standard industry practices abroad, which will be adapted where required to suit Indian market conditions.

lakshaybuildtech undertake turnkey project for architectural solution, design, engineering, supply & installation of steel buildings and steel structure system. Company also undertake project management services with civil foundation design work.

Site execution work is carried out through our certified builder network who undertake to install the building/structure and associated work on behalf of the company in line with company specifications and standards .Company’s qualified Engineers and designers checks & approve the final work before handover.

The main farming of PEB systems is analyzed by the stiffness Matrix method using in-house software. The design is based on Allowable stress Design (ASD as per the American Institute of Steel Construction (AISC) specification. The design program provides an economic and efficient design of the main frames and allows the users to utilize the program in different modes to produce the frame design satisfying the engineer’s requirements. The program analyzes and designs the frame based on the given geometry and loading and the desired load combinations as specified by the building code opted by the user. The program operates through the maximum number of cycles specified to arrive at an acceptable design.

AISC : American Institute of Steel Construction Manual.

AISI : American Iron and Steel Institute Specifications.

MBMA : Metal Building Manufacturer’s Association Low Rise Building Systems manual.

ANSI : American National Standards Institute Specifications.

ASCE : American Society of Civil Engineers

UBC : Uniform Building Code

IS : Indian Standards.

Company uses the following main design software for the Design for Pre-engineered buildings:

The frame data is assembled based on the number of frame members, number of joints, number of degrees of freedom, the conditions of restraint and the elastic properties of the member. Based on this, the data is stored and the member section properties are computed. The overall joint stiffness matrix is generated based on the above frame data by summation of the individual stiffness matrices considering all possible displacements. The load vector is then generated based on the loading data and the unknown displacements are obtained by inverting the overall joint stiffness matrix and multiplying with the load vector.

Knowing the free joint displacement, the member and actions are obtained by back substitution. The axial, shear and bending forces are then transformed to the section neutral axis and the additional moment created by the eccentricity of the thrust is added to the moment value. These values are generated for different load combinations and the final design checks are preformed

The allowable stress values are computed as per the AISC specification with due consideration, for the web depth/thickness ratios and the flange width/thickness ratios with the appropriate correction factors as per AISC.

For computation of the allowable bending stresses, the effective un-braced lengths for each segment are used based on the brace point locations defined by the user. The effective length factor K is used for calculating the slenderness ratios in order to compute the allowable axial stresses. The coefficients for bending are calculated based on the end conditions for each member and the corresponding end moment values. The stress ratios are then computed as actual/allowable stresses and are then combined to check that the total aggregate is under unity.

The joint displacements and support reactions are reported for various load cases and combinations along with the clear heights at haunch and peak to check for clearances.

A detailed connections report is generated based on the forces acting at all the splice joint and designed as per the specification of AISC. The connections used in the super structure for all the main frame splices conform to the specifications of ASTM a 325 for High strength friction grip bolts. The anchor bolts will be of ASTM A 307 material Grade 36.

Unless otherwise specified by client, the serviceability criteria are based on MBMA and standard industry practices. Following are the brief extracts from these specifications.

When client requires the serviceability criteria as per IS codes, the design deflections will be complied accordingly.

All materials are purchased new direct from the steel mills with certified Mill certificates complying with ASTM or equivalent specifications. Company maintains a large stock of Plates, Bars, Black coils, Galvanized coils, Sheeting coils and various building accessories required to support the production levels. All the material specifications are documented in the Company’s Specification Manual, which is an integral part of the total quality control system at factory. High strength steel having minimum yield strength of 345 Mpa is used for Primary, secondary and cladding.

The materials are subject to stringent quality control checks upon receipt at plant and only upon approval are taken into stock. The material inspection system is well documented in company Quality Control Manual and compliers with material tractability and other requirements specified in ISO9001.

The manufacture of the building is done in accordance with relevant American Codes. Welding is performed by pre-qualified welders using approved welding processes as per structural welding code AWSD1.1 published by the American Welding Society. The built-up sections are welded in an automatic CONRAC welder using submerged arc welding process. The aplice plates and other attachments are welded by the Inner shield or CO2 welding process. All butt welds are full penetration welds. Stage inspections are carried out at various stages in the manufacturing process and results documented. The welds are subject to NDT tests including Dye penetrate inspection (DPI), Magnetic particle Inspection (MPI), Ultrasonic Testing (UT) or Radiography, as required by contract specifications. A 100% visual and dimensional check is performed on all members. Manufacturing tolerances are in accordance with MBMA and AWS specifications.

The standard surface treatment for fabricated steel is mechanical wire brushing to SSPC ST3 and application of one coat of red oxide prior to a nominal dry film thickness of 25-30 microns. However company offers various types of surface preparation and epoxy paint systems to suit the corrosive conditions at site and contract requirement. Company has blast cleaning facility to achieve a white metal finish to Swedish standard SA2 ½ or SA 3 and airless spray facility to apply any specified paint system. Upon request company will recommend the optimum paint system to suit ambient conditions at site.

Our Company provides Erection drawing procedures manual, which includes all the information required for the site assembly of the building. The erector must use to proper tools and equipment and sequence of erection as specified in company manual. The high strength bolts at the primary connections are pre-tightened to specified tension or torque as shown in the erection drawings. The method of tightening may be either using a calibrated tension or torque wrench or turn-of-the-nut method as specified in AISC Manual. Erection should always start with a braced bay and the red steel must be fully plumbed before starting cladding erection. Erection tolerances are as set forth in AISC Code of Practice except individual members are considered plumb and aligned if the deviation does not exceed 1:300 as per MBMA specifications.

In order to have long life cycle of the building with virtually nil maintenance cost, it is necessary to have periodic cleaning of the building. User should consult supplier for Building maintenance manual.

We undertake complete Pre-Engineered Building (PEB) designing as per your needs , manufacturing at our factory, painting , dispatch and erection at your site Pre- Engineered Buildings are custom designed as per customer needs by experienced engineers which comprises mainly of :-